Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

We are the best foundry companies supplier manufacturer of stainless steel die casting.Stainless steel castings, as the name suggests, are a general term for the production of steel castings with various stainless steel materials.

Our die casting process is specifically designed for petroleum machinery parts, ensuring smooth and efficient operation. Made primarily of high-quality stainless steel, our die cast parts are durable and reliable. As a leading supplier and manufacturer of stainless steel die casting, we are committed to providing the best foundry services to our customers.

Precise for Complicated Parts:

Our parts are designed to work seamlessly with other components, ensuring efficient and reliable operation. This is especially true for complex or intricate parts, which are both practical and cost-effective. Our commitment to quality and precision ensures that our parts are built to last and perform at the highest level.

Durable and Long-lasting:

Its exceptional strength and resistance to corrosion ensure that parts made from stainless steel are long-lasting and reliable. This makes it an ideal material for use in a wide range of industries, including the petroleum machinery industry, where parts must withstand harsh environments and heavy use.

Good Corrosion Resistance:

Petroleum machinery operates in harsh environments that expose it to corrosive chemicals and high temperatures. This can cause parts to degrade and fail over time, leading to costly repairs and downtime. However, stainless steel is highly resistant to corrosion, making it the ideal material for petroleum machinery parts. Its resistance to corrosion ensures that parts remain functional and reliable over time, even in the harshest of environments.

Cost Effective:

Stainless steel casting is a highly cost-effective manufacturing process that allows for the production of large quantities of parts quickly and efficiently. This is because stainless steel casting is a highly automated process that requires minimal labor and can produce parts with high precision and accuracy. Additionally, the use of stainless steel as a material for casting is cost-effective due to its durability and resistance to corrosion, which reduces the need for frequent replacements and repairs.

Versatile:

Our range of casting parts for petroleum machinery includes roller bushings, roller shafts, bearings, and more. If you require other parts, we are happy to work with you to provide customized solutions to meet your specific needs. As a well-known supplier in China, we are committed to providing our customers with the best products and services. Our team of experts is dedicated to ensuring that you receive the highest quality parts that are tailored to your unique requirements.

lCorrespondingly, the pouring temperature is also high. The interaction between molten steel and casting material at high temperature is very easy to produce sticky sand defects. Therefore, artificial quartz sand with high refractoriness should be used as a casting mold.

lBrush the coating made of quartz powder or zirconium sand powder on the surface of the stainless steel casting. In order to reduce the source of gas, improve the fluidity of molten steel and the strength of the casting mold, most steel castings are cast with dry or quick-drying molds, such as Using CO2 hardened water glass sand mold.

Because the shrinkage of stainless steel precision casting is much larger than that of cast iron, in order to prevent shrinkage cavities and shrinkage porosity defects in the casting, we will use cold iron, subsidies and risers to achieve sequential solidification in the casting process.

Stainless steel castings have been used in different industries and used in various media corrosion conditions. It is deeply welcomed by everyone due to its good casting process characteristics.

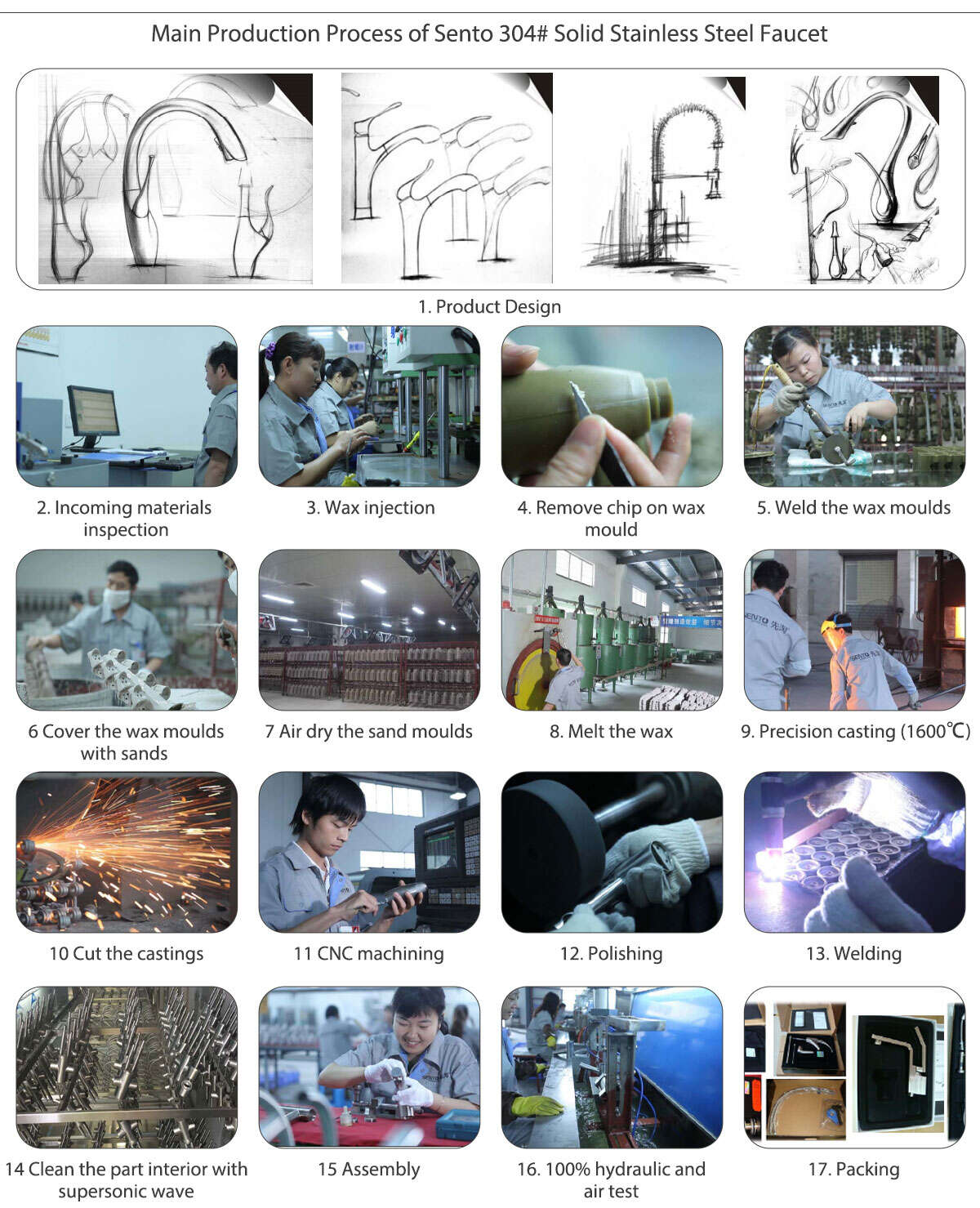

Sento Introduction

Sento,world class stianles steel faucet manufacturing enterprises,is the founder of stainless steel faucet in China,Founded in 1999,its former named is Huangqi Qinglian Hardware Machinery Factory,At the beginning of 2000,with an idea of making faucet with healthier,more environmentally freindly and durable materials,the two over fifty years old Sento's founder Mr Kong Qingyi and Mr Shen Zemin,overcame numerous processand technical difficulties,sucessfully invented the first SUS304 stainless steel faucet in the China.In the subsequent dacades,under the leardership of the two Sento's founders,with the concept of "quality the first,cost the second",we focus on research and development of SUS304 stainless steel faucet,continue to promoted technological innovation of stianless steel sanitary ware industry,train a large number to of technical elite for the industry,and has driven the development of the whole stainless steel faucet manufacturing industry.

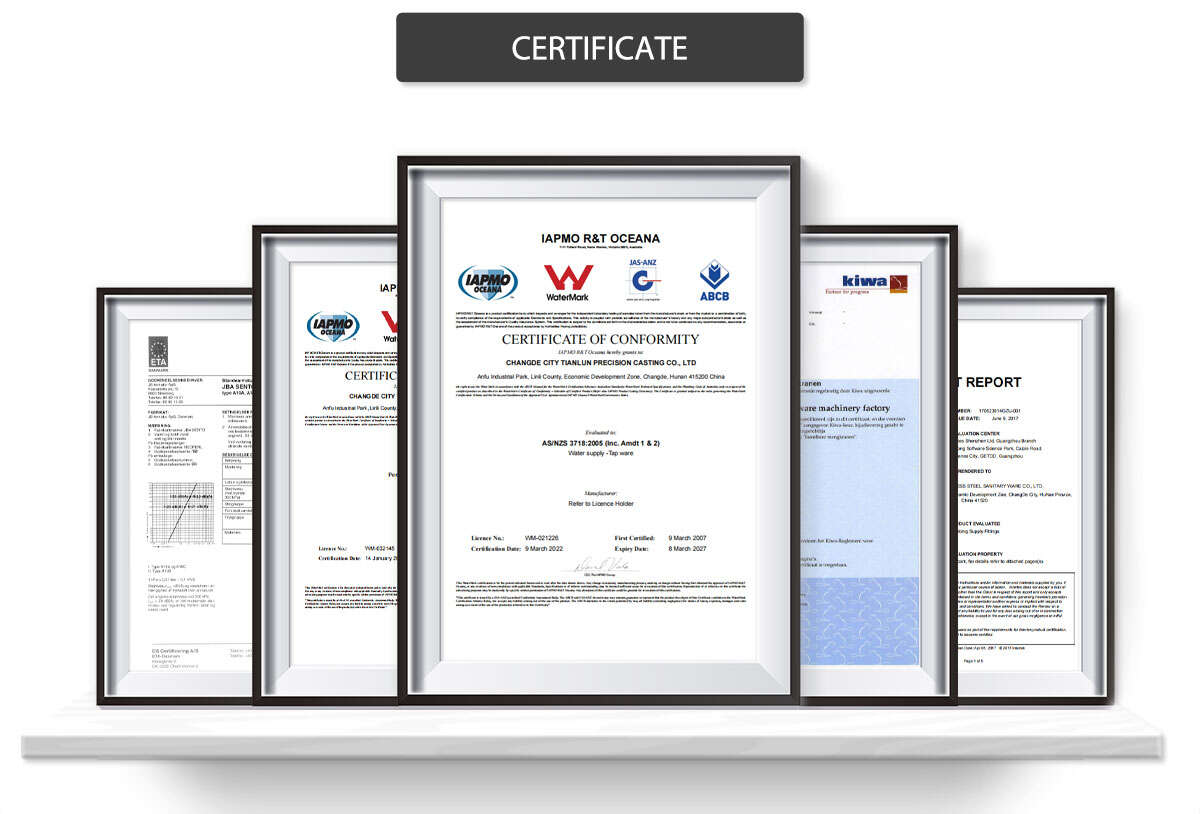

Sento's products cover stainless steel faucet,stainless steel shower and shower column,stianless steel bathroom cabinet,stainless steel sink,stainless steel kitchen pendants,stainless steel floor drain ,etc.They are sold to nearly 90 countriesand regions,and are wildely used in villas,high-end communities,comercial office buildings and public places,Sento is the only domestic enterprise which passed seven international certifications,including Holland KIWA,Australia water mark,America SGS ,UPC,European EN-817,Denmark VA,HongKong water supplies department WARS detection.

In recent years,Sento stainless steel faucet continuous unveiled at the top three industry events.including Shanghai international exhibition kitchen,Germany Frankfut ISH international kitchen exhibition and USA KBIS international show.It attracts all attention inside and outside the industry .Sento has won the top 100 Kitchen Bathroom Enterprises.Chinese Manufacturing Beauty,Canton fair "CF" award,and other awards.

In the future,in order to build up a wold class stainless steel faucet kitchen and bathroom brand with great competitiveness and influence,we will adhere to the strictness,good quality and perfectionism.We will bring a healthier,more environmentally freindly,and better high-end kitchen and bathroom products.